centrifugal pump for oil|explain working of centrifugal pump : trading Versatility: Centrifugal pumps can cater to a wide array of needs, ranging from simple, domestic water lift applications to demanding tasks in wastewater treatment plants or oil refineries. Efficiency: These pumps are very efficient for handling low-viscosity fluids and high flow rates. If autoclaving bagged waste, make sure the bag is loosely taped so that steam can enter .

{plog:ftitle_list}

View and Download GNATUS Autoclave Bioclave 12L owner's manual online. Autoclave Bioclave 12L dental equipment pdf manual download.

Choose from our selection of oil centrifugal pumps, including circulation pumps, high-efficiency circulation pumps, and more. In stock and ready to ship.

how to correct refractometer reading for alcohol

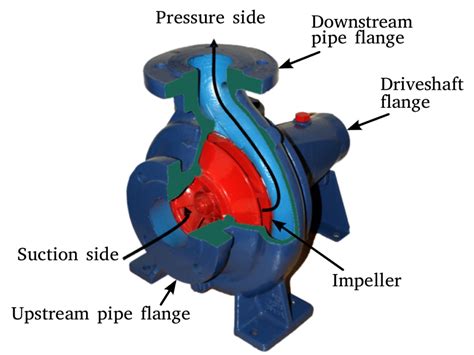

With a design heritage dating back to 1959, our centrifugal pumps are well proven in power generation, oil and gas, and industrial applications around the world. For oil and gas in particular, we make a wide range of API 610/ISO13709 .Oil & gas is an industry where efficiency and safety are indispensable requirements, and the Boulton Pumps centrifugal pump range offers tremendous guarantees and allows our natural resources to be processed safely and reliably.Warman centrifugal pump in a coal preparation plant application A pair of centrifugal pumps for circulating hot water within a hydronic heating system. Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor.

Versatility: Centrifugal pumps can cater to a wide array of needs, ranging from simple, domestic water lift applications to demanding tasks in wastewater treatment plants or oil refineries. Efficiency: These pumps are very efficient for handling low-viscosity fluids and high flow rates.The XTO end suction, single stage centrifugal thermal oil pump can be used for thermal oil that is free of solid particles. Common fluids pumped include thermal oil, heat transfer oil, bitumen and low viscosity high temperature industrial oils and common applications include steel plants, plastic manufacturing facilities, heat transfer circulating systems, and the rubber and wood processing .2 Centrifugal Pump Selection Guide See page 4-5 table for list of eight color-coded market designations. . ITT Goulds Pumps is among the most widely recognized and respected brands in the global pump industry, serving customers in the oil and gas, mining, power generation, chemical, pulp and paper, and general industrial markets. As the only .

Centrifugal pumps are widely used in gas and oil industries for pumping slurry, mud, and oil. These pumps are also valuable for sewage systems. These are employed by the industrial and fire protection sectors, including sprinkler systems for fire protection, heating and ventilation, boiler feed applications, air conditioning, and pressure boosting.

In the dynamic world of oil and gas production, centrifugal pumps play a pivotal role in moving fluids efficiently and safely. To ensure the reliability, performance, and consistency of these critical components, the American Petroleum Institute (API) developed API 610, a globally recognized standard for centrifugal pumps used in the oil, gas, and petrochemical industries.

Centrifugal pumps are generally designed and suitable for liquids with a relatively low viscosity that pours like water or light oil. More viscous liquids such as 10 or 20 wt. oils at 68-70 deg F will require additional horsepower for centrifugal pumps to work.

Oil in process pumps are typically an ISO grade 32, 46, 68, or 100. These numbers relate to the Kinematic viscosity in centistokes. The oil is usually hydrocarbon oil, although synthetic oils are sometimes used for specific lubrication applications.Rotherm Hot Oil Pumps. RHS Series Split Case. 1600 Series Close Coupled. Gear Pumps. Ball Check Valves. 3100 Series NPT Threaded Valves. 5100 Series Flanged Valves. Vertical Pumps. RVMS Series Vertical Multistage. . Acid pumps, Horizontal Centrifugal End suction Pumps, Hot Oil Pumps, Our Products. Here are practical guidelines and useful recommendations for centrifugal pumps in different oil, gas, petroleum and petrochemical services. Centrifugal Pumps. The most common pump type used across industries is the centrifugal pump. This is because of their flexibility, reliability, favored head-flow rate relations, reasonable prices and well .

A centrifugal pump is used to move water and other low viscosity liquids with the assistance of centrifugal force. The pump uses a motor that converts electric energy into mechanical energy. This energy initiates the rotation of the pump’s impeller and helps move the liquid from a lower to a higher level.Recent trends in oil and gas projects have demonstrated substantial budget and schedule overruns. The Oil and Gas Community within the World Economic Forum (WEF) has implemented a Capital Project Complexity . Centrifugal Pumps, which is an identical adoption of ISO 13709:2009 with the same title, for application in the

1. Centrifugal Pumps. Centrifugal pumps are the most common types of pumps used in the oil and gas industry. Centrifugal pumps use centrifugal force through the rotation of the pump impeller to draw fluid into the intake of .Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. As illustrated in Figure 13, two identical centrifugal pumps operating at the same speed with the same volumetric flow rate contribute the same pump head. Since the inlet to the second pump is the outlet of the first pump .Centrifugal Pumps for Thermal Oil or Hot Water Applications PRODUCTS BRANDS SOLUTIONS Industries Service & Support About Search Blog Careers News Events English Chinese Japanese Centrifugal pumps, engineered for operational flexibility, efficiency and durability, meet the pumping needs of many oil and gas applications. With this recent 21st Century U.S. oil and gas boom is the increased need for oil producers to get .

Centrifugal pumps are extensively used in the oil and gas industries and the pump performance drops with higher viscosity and higher surface roughness of the pump impeller, and the impeller design parameters have significant effect on the pump performance. Through the present research, crude oil pumping behavior has been predicted, analyzed and compared .

Centrifugal, oil, positive displacement, oil transfer, diaphragm, and petrochemical pumps are essential in delivering oil from the ground to a tanker, then to a refinery, and then on to storage. They are also useful for methanol injection, glycol pumping, chemical processing, gas sweetening, and water disposal.

types of centrifugal pump mechanisms

Axial Flow Contact Us Pumps Thermic Fluid/Hot Oil Centrifugal Pump About UsIndustrial Pump Manufacturers About Us Denwell Fluid Controls is a leading Manufacture & Exporter of high-quality industrial pumps and valves. We are committed to providing our clients with the best products and services, backed by our years of experience in the industry.Our centrifugal Pumps are one of the most commonly used industrial pumps for pumping Oil. Our pumps are widely used because of the lower cost and ease of installation. Easy mechanism coupled with other advantages has to lead to commendable market size.Learn about different types of centrifugal pump and working principles. Also, learn about API 610 pumps such as OH, BB, and VS types. . You can simply say that it is high pressure – low flow rate pump. Most pumps used in oil and gas will fall into this category. Axial Flow Pump.

Centrifugal pumps are devices used to move liquids from one point to another by utilizing centrifugal force. They consist of a casing, impeller, shaft, and motor. The impeller, a rotating disc with vanes, is the heart of the pump. The inclusion of a BS&W bowl has been added to the latest version of the American Petroleum Institute (API) 610 centrifugal pump standard used by the refining, petrochemical and natural gas industries. IMAGE 5: BS&W bowl showing clear oil discoloration. 3. Oil Color. Whenever oil degrades, the color and clarity of the oil can change. : Performance Curve of Centrifugal Pumps 26 Figure 11 : Specific speed variations of different types of pump 28 Figure 12 : double-acting piston pump 32 Figure 13 : Positive-displacement gear-type .

oil centrifugal pump for sale

Find Autoclavable Bags manufacturers, suppliers, dealers & latest prices from top companies in India. Buy from a wide range of Autoclavable Bags online.

centrifugal pump for oil|explain working of centrifugal pump